SEM and TEM sample preparation of materials

Diversity of techniques for sample preparation

In the context of electron microscopy, the term “materials” covers a broad range of substances including metals, rocks, ceramics, polymers, dry biological samples etc. The preparation methods required, if any, may depend on such as:

- Original size/shape

- Examination of external structure or internal microstructure

- Conductivity of sample e.g. conductive coating of non-conductive materials

- Mode of examination e.g. Specimen imaging, Energy Dispersive Spectroscopy (EDS), EBSD.

Preparation may therefore include techniques such as: sectioning, mounting in conductive resin, grinding, polishing, chemical-etching, jet electro-polishing (for TEM), and coating (gold or carbon). Our sample preparation service can offer some, or all, of the preparation methods required to prepare such samples for SEM or TEM.

TEM sample preparation

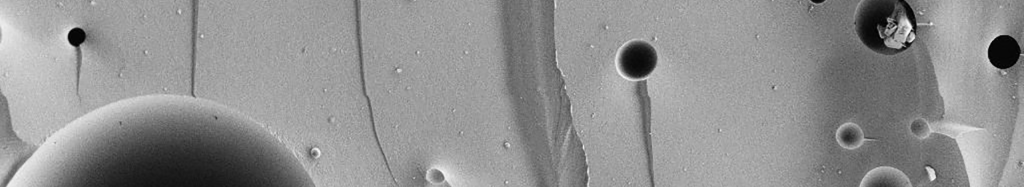

Materials such as nanoparticles are simply dispersed onto TEM grids using suitable solvents, and air-dried before TEM imaging.

Metals are prepared as thin (<50 micron) 3 mm diameter discs that are then used to create thinned-hole edges for TEM examination. This preparation for TEM involves several steps. They include multi-stage cutting, machining e.g. electro discharge machining (EDM), grinding, polishing of metals and jet-electropolishing.

Larger solid materials can be prepared for TEM by extracting micro-scale sections from the material by FIB-SEM (Focussed Ion Beam SEM). The sections are then mounted onto a TEM grid.

The process for TEM sample preparation

Once the nature and number of samples to be prepared for TEM is agreed, we will proceed to prepare the samples using the appropriate method(s). The number of individual processes may depend on the initial size and form of the material.

In some cases, e.g. preparing 3 mm diameter metal disc specimens for TEM, we may recommend preparing multiple examples (2-3) of each sample. This is because some preparation steps must be done individually leading to slight variations in the final quality of finished example.

SEM sample preparation

Due to our SEM’s large specimen chamber, SEM sample preparation may be minimal, depending on the sample. However, the sample preparation may involve many of the processes referred to under TEM preparation.

For example, examination of a metallic microstructure in a sample may involve cutting or machining to produce smaller samples suitable for resin-mounting. After the samples have been mounted in resin, they are semi-automatically grinded and polished with a diamond in order to achieve a sub-micron finish. Lastly, the samples undergo chemical etching to reveal their grain structure. These operations can normally be carried out on multiple (up to 6) samples simultaneously. Rock samples can be similarly prepared.

Non-conductive samples or poorly-conductive samples may be coated with carbon or gold. Both coating methods can be performed on multiple samples simultaneously (up to 6), depending on the sample sizes.

The process for SEM sample preparation

Samples for SEM are normally mounted on aluminium stubs (12 mm or 25 mm diameter) using conductive sticky pads, conductive glue and/or conductive copper tapes. Stubs of up to 8 x 12 mm, or 3 x 25 mm can be accommodated on the SEM stage. Larger or more awkwardly shaped samples can be placed onto other mounting stages.

Once mounted on stubs, non-conductive samples will be coated in a thin layer of carbon or gold depending on the aims of the SEM microscopy. Carbon may be preferred where elemental analysis is required (Energy Dispersive Spectroscopy EDS or EDX) as it interferes less than gold with the spectral results.

FAQ

The cost very much depends on the technique selected, as TEM is more time consuming, it is more expensive. The next thing that will affect the cost is the type and number of samples required, and how much work is needed to prepare it for processing.

The preparation of a sample for SEM that does not need workshop preparation can be very simple. Assume we prepare 1-5 such samples. The whole process is likely to cost £45, Assuming that attaching the samples to the stubs in the first place is a straightforward operation, they can be coated as a batch. If only 1 sample is prepared for SEM, the cost will still be £45.

For example, preparing TEM samples from a bulk metal sample may involve use of workshop facilities and staff time to produce thin discs. These disks must be mechanically thinned and polished further by hand, before being individually jet electro-polished. The finished sample then has a hole which has edges thin enough to transmit the TEM electron beam successfully. In this example, 1 sample would cost around £150. However, the price will be £50/sample if 5 samples are prepared simultaneously since certain procedures can be batched.

This depends on the technique – SEM is generally faster and may take only hours to a few days.

On the other hand, sample preparation for TEM may take longer – if initial preparation stages require workshop time it could be around 10 days from start to finish.

This depends on the technique – SEM is generally faster and may take only hours to a few days.

On the other hand, sample preparation for TEM may take longer – if initial preparation stages require workshop time it could be around 10 days from start to finish.